Our technology: Organic photovoltaics (OPV)

Organic photovoltaics (OPV) uses materials from the field of organic chemistry to convert sunlight into electrical energy. In a way, OPV is the “brother” of the now widely established Organic LED (OLED) technology that uses organic chemistry materials to convert electricity into light. The counterparts of OPV and OLED are the established PV and LED technologies, built around inorganic materials, such as silicon in the conventional PV. The physical principle how sunlight is converted in electricity is identical to the organic and inorganic technologies, but the main difference is in the materials themselves. Inorganic materials often contain of toxic substances, are increasingly subject to scarcity concerns, and in general are very hard to dispose of in an environmentally friendly way. On the other hand, organic materials and in particular the ones that Heliatek has invented, are not toxic, comprise of extremely abundant naturally occurring elements, and are very easy to dispose at the end-of-life in an environmentally friendly way.

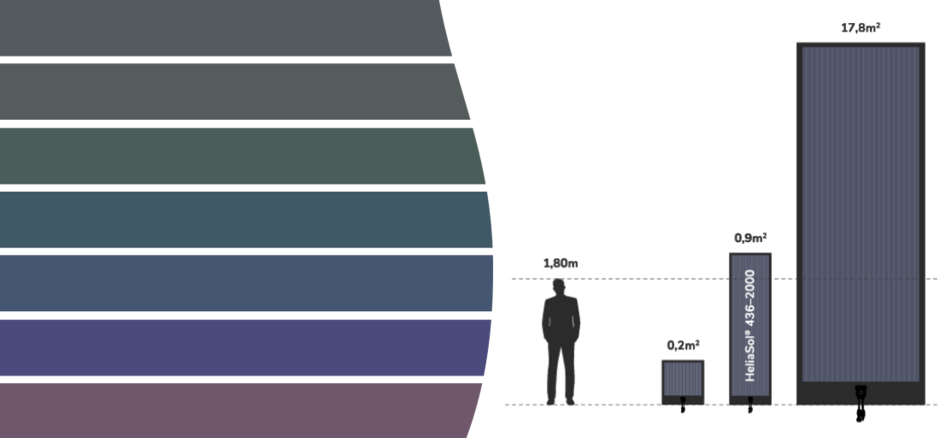

The materials of the organic solar stack developed by Heliatek are particularly innovative and are protected by Heliatek’s comprehensive IP portfolio. The organic stack in our solar films consists of many individual layers but has a total thickness of only less than a thousandth of a millimeter. As a result, our solar films have unique properties: They are ultra-light, flexible, ultra-thin, and truly green. This makes them the perfect choice for all surfaces and applications where conventional PV modules do not fit, additional cost for mounting structures is required or building codes do not allow it.

Organic photovoltaics unlock new possibilities for building owners, building management companies and solar installers to enable an acceleration of the transformation to net-zero energy buildings and carbon neutral economies. Unlike most inorganic technologies, Heliatek’s OPV is not limited by the basic properties of the semiconductor material. On the contrary, OPV is like a toolbox with a growing variety of materials having specific combinations of properties. This will continue to unlock additional applications by further increasing the efficiency but also in terms of the variety of designs (different colors and even transparency).

More than 450 patents

Heliatek is the globally recognized market leader in organic photovoltaics. Since its foundation, Heliatek has continuously expanded its know-how and protected it with more than 450 patents*. Patents include the protection of organic solar cells with our proprietary absorber molecules, as well as the special cell layout. In addition, we have patented important processes to protect the unique know-how of our production.

*Granted and pending patents

Proprietary developed research production line

Heliatek has developed and built its own research production line, which was commissioned in 2012. Moreover, Heliatek has created its own development and testing facilities with extensive internal testing procedures and tools. In this way, a unique-to-the-world production process – thermal evaporation under vacuum in a roll-to-roll process was established and transferred to the current series production. According to the “Lab-to-Fab” transfer concept, we can test and further develop the latest research results in our research production line and then transfer these directly into series production. This efficient step is an important link between research and series production and helps us to transfer the latest findings efficiently into our series product.

Outstanding achievements

Heliatek has already set several records for efficiency. In 2016, we achieved an efficiency of 13.2% under laboratory conditions, which was the highest efficiency ever achieved by an organic solar cell at that time. We have set ourselves ambitious targets and have drawn up a clear roadmap to further increase the efficiency of our organic solar cells in the years ahead. Since 2016 we have focused our attention from establishing world records in a lab-environment towards realizing an efficient and fast “Lab-to-Fab” transfer. We are constantly developing the materials used in our solar cells to enable the use of the largest possible solar spectrum for electricity generation. This will allow us to achieve higher levels of efficiency in the future. Our unique knowledge of organic chemistry will help us to further optimize the electricity generated by the active layer while minimizing losses in the surrounding protective layers. The existing potential has by far not been exploited, because unlike the dominant silicon technologies, we are still far from achieving the upper limit of efficiency, which is estimated for our organic stack to be above 40%.

Future potential

With HeliaSol, our ready-to-use solar film is available now. Of course, we will keep on expanding our "OPV toolbox" towards more versatile, powerful, and ubiquitously applicable solutions for solar energy generation. Additionally, with HeliaFilm, we will be able to offer OPV components to be integrated in construction elements. In principle, the technology still offers a lot of potential, such as different colors, different sizes, but also transparent solar cells.